Die cutting is a popular technique used in various industries, from packaging and printing to crafts and textiles. It’s a versatile process that allows for the creation of precise shapes and designs by using a die, which is a specialized tool used to cut or shape materials. In this article, we will explore what die cutters are, how they work, and how you can use them for different applications.

What is a Die Cutter?

A die cutter is a machine used to cut, shape, or form materials like paper, cardboard, fabric, rubber, plastic, and more into specific shapes or patterns. The process involves using a die, which is a steel blade that matches the desired shape. The die is pressed into the material using pressure, cutting it into a pre-designed shape. Die cutting is commonly used for mass production of products, but it’s also used in smaller-scale applications like craft projects.

Types of Die Cutters

There are several types of die cutters available, each suited for different needs and materials. Here’s a look at the most common types:

-

Manual Die Cutters

- Overview: Manual die cutters are hand-operated machines that require the user to physically turn a crank or handle to apply pressure to the die. These machines are typically used for smaller, precision cutting tasks in crafts, scrapbooking, and small businesses.

- Advantages:

- Affordable and easy to use.

- Ideal for small batches or personalized items.

- Compact and portable.

- Considerations:

- Limited cutting capacity and speed.

- Requires manual effort and can be tiring for large volumes.

-

Digital Die Cutters

- Overview: Digital die cutters are more advanced machines that use computer software to control the cutting process. These cutters can automatically cut complex designs and patterns, often making them suitable for larger production runs or intricate designs.

- Advantages:

- High precision and accuracy.

- Can cut a variety of materials and more complex designs.

- Automated process, saving time and effort.

- Considerations:

- Higher upfront cost compared to manual die cutters.

- Requires technical knowledge to operate the software and machine.

-

Rotary Die Cutters

- Overview: Rotary die cutters use a cylindrical die that rotates around the material being cut. This type of die cutting is commonly used in high-volume production, especially for items like labels, packaging, and corrugated materials.

- Advantages:

- High speed and efficiency for large production runs.

- Ideal for continuous cutting of thin materials like paper, plastic, and film.

- Considerations:

- Expensive and large in size, making it less suitable for small operations.

- Requires a specific type of material and design for optimal results.

-

Flatbed Die Cutters

- Overview: Flatbed die cutters use a flat die that presses directly onto the material to make the cut. These machines are versatile and can handle a wide variety of materials, including thick paper, cardboards, plastics, and fabrics.

- Advantages:

- Highly versatile and can handle different materials.

- Capable of cutting thick and heavy materials.

- Considerations:

- Slower than rotary die cutters, especially for large volumes.

- Larger and more expensive than manual die cutters.

-

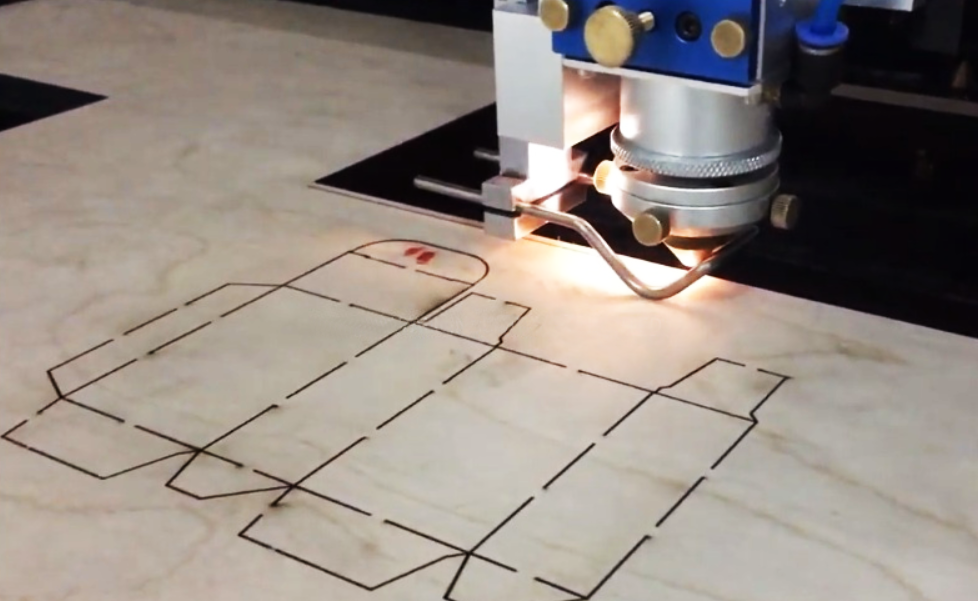

Laser Die Cutters

- Overview: Laser die cutters use a focused laser beam to cut or engrave materials with high precision. Unlike traditional die cutting, which uses physical pressure, laser cutting uses heat to vaporize or melt the material, creating a clean cut.

- Advantages:

- Extremely precise and able to cut intricate designs.

- Can cut a variety of materials, including metals, wood, plastics, and fabrics.

- Minimal material waste due to the precision of the laser.

- Considerations:

- High cost for both the equipment and maintenance.

- Can be slower compared to other die cutting methods for larger volumes.

How Die Cutters Work

The die cutting process typically involves the following steps:

-

Creating the Die: A die is made to match the shape or pattern that you want to cut. The die is usually made from steel and shaped into a sharp edge to ensure it can cut through the material.

-

Positioning the Material: The material to be cut is placed onto the cutting surface, whether it’s paper, fabric, plastic, or another material.

-

Applying Pressure: In manual die cutting, the user applies pressure using a crank or handle. In digital, rotary, or laser die cutting, the machine applies the necessary pressure or laser heat automatically to cut the material.

-

Removing the Cut Material: Once the die has cut through the material, the finished shapes or pieces are removed, and the process is repeated for subsequent pieces.

Applications of Die Cutters

Die cutters are used in a wide variety of industries and applications. Some common uses include:

-

Packaging: Die cutters are frequently used to cut cardboard, paperboard, and other materials into specific shapes for packaging, such as boxes, cartons, and labels.

-

Crafts and Scrapbooking: Die cutting is a popular technique in the crafting community, used to create intricate shapes, cards, invitations, and other personalized items.

-

Textiles: Die cutters are used in the apparel and fashion industry to cut fabric into specific patterns or shapes for clothing and accessories.

-

Automotive and Manufacturing: In industries like automotive and manufacturing, die cutting is used to create gaskets, seals, and other parts from rubber, foam, and plastic.

-

Printing: Die cutters are often used in printing for creating custom shapes for business cards, brochures, and other marketing materials.

Benefits of Using Die Cutters

-

Precision and Consistency: Die cutting allows for highly accurate cuts with consistent results, making it ideal for mass production and intricate designs.

-

Speed: Die cutting is fast, especially when using automated or digital machines, making it efficient for large production runs.

-

Versatility: Die cutters can handle a wide range of materials, including paper, plastics, fabrics, and metals, offering flexibility across different industries.

-

Cost-Effectiveness: For large production volumes, die cutting can reduce labor costs and material waste, ultimately making it a cost-effective choice.

Conclusion

Die cutters are an essential tool for anyone looking to create custom shapes and designs with precision and efficiency. Whether you’re working in packaging, textiles, crafts, or manufacturing, die cutting offers numerous benefits, including speed, accuracy, and versatility. Choosing the right type of die cutter depends on factors such as material, production volume, and design complexity. With the right die cutter, you can streamline your production process and deliver high-quality, customized products with ease.

Related posts:

- Professional Golf Iron Fitting – Tailored for Peak Performance

- Car-Hailing Software Market 2025: Growth Drivers and Opportunities Outlook to 2033

- Elevate Your Marketing Game with Eye-Catching Pop Up Banners and Pamphlets in San Francisco – AlphaGraphics Downtown

- Global Demand to Boost Finished Lubricants Market by 2034

Leave a Reply