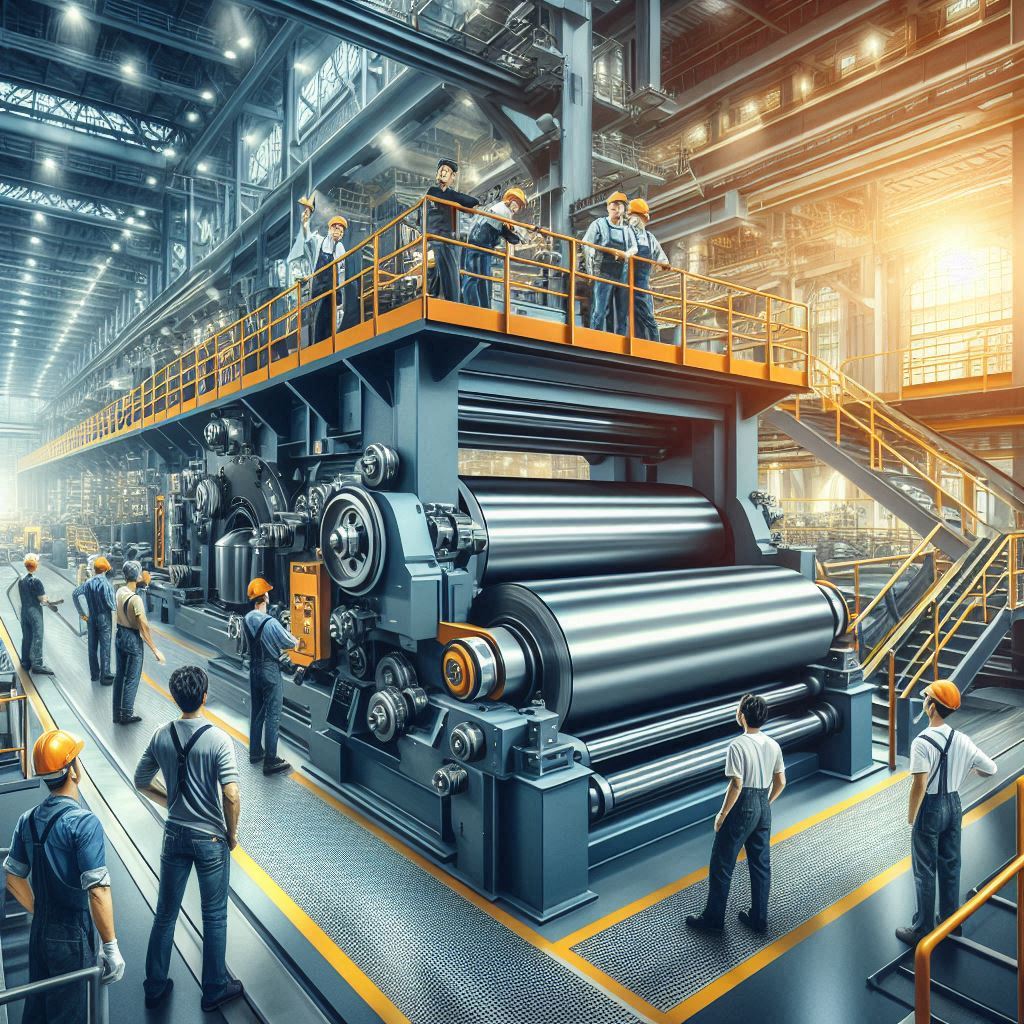

Indeed, having to transform the role of an industry as much as the metalworking industry in the manufacture, construction, and infrastructure process, steel rolling machines would definitely stand out among the many innovations that turned this particular sector. Not just for shaping differently and bringing efficiency, reduced material loss, and increased production speed, it practically revolutionized processing of metals. Let’s see how the steel-rolling machines have affected the metalworking industry.

1. Improved Production Efficiency and Productivity

The work of smashing the metals into shapes is an ancient practice that consumes a lot of energy with manual operations long before the development of these steel rolling machines. Methods were time-consuming, hence not suitable for bulk production and precision and consistency were other areas where productivity was lacking. Steel rolling machine unit has replaced the work done by a human, which saw quite an increase in production. The new system currently involves CNC-controlled and automated machines rolling steel plates in large volumes while not involving the human factor, and this translates to quick turnaround times with higher output results.

2. Enhanced Accuracy and Consistency

Precision is vital for work in metal manufacturing, especially in fields like the automobile manufacture, aerospace, and construction. Steel rolling machines make their parts with a uniform thickness and finish, as well as specific bend angles. CNC and hydraulic rolling machines often serve computer-controlled pressure and movement, negating chances for human errors, thereby ensuring repeatable, high-accuracy contours all the time. Resulting benefits are in terms of enhanced quality control and diminished defective products.

3. Cost Savings and Material Economy

A major challenge facing metalworking today is wastage of materials. Most classical rolling methods produced more scrap, thus translating to a higher cost with less profit margin. Steel rolling machines work in perfect economical dimensions with minimum waste by achieving full usage of the materials. Automated feeding, accurate calibration, and up-to-second monitoring allow production efficiency that leads to improved savings. This further makes steel rolling machines cost-effective for companies.

4. Flexibility with Types and Applications

Steel rolling machines are as versatile and widely applied as the industries for which they are made: auto industry-manufacturing vehicle chassis and fuel tanks; construction industry-shaping beams, pipes, and curved metal structures; shipping-forming huge metal sheets into ship hulls and other marine structures; aerospace-making components for aircraft-all with extremely high precision; boiler and pressure vessel fabrication-manufactures very thick rolled plates for tanks in industry and boilers.

There are different types of steel rolling machines like mechanical, hydraulic, CNC, and four roller machines that are manufactured by Steel rolling machine manufacturer that can be selected based on individual needs of businesses.

5. Advancement in Technology for Automation

The growth of the metalworking industry is accompanied by an avalanche of advances in automation and smart manufacturing. It is the state-of-the-art of modern steel rolling machines that even incorporate IoT connectivity, AI-driven monitoring, and predictive maintenance systems for machines. This type of technology allows the manufacturers to see their operations even in real time, predicts faults even before the breakdown of the machine, and optimizes the process for maximum efficiency in production.

Conclusion

In conclusion, it can be said that steel rolling machines have changed the way of dealing with metal production, making the processes faster and more precise in terms of cost. CNC technology advancement as well as automation in the present states, combined with AI safety features, further carry on the enhancement of efficiency while waste is reduced along with improved quality standards across industries. Steel rolling machines will still be one of the principal movers in innovation and progress for the metalworking sector as the world’s demand increases in metal products since assuming precision.

Leave a Reply