In the world of industrial applications, rollers play a crucial role in material handling, manufacturing, and automation processes. When it comes to durability, efficiency, and reliability, polyurethane rollers stand out as the preferred choice for many industries. High-quality polyurethane rollers offer enhanced performance, excellent wear resistance, and superior longevity compared to rubber or metal alternatives.

If you are in search of a trusted manufacturer for premium polyurethane rollers, you’ve come to the right place. This blog will explore the advantages of polyurethane rollers, their applications, and why choosing the right manufacturer is critical for your business success.

What Are Polyurethane Rollers?

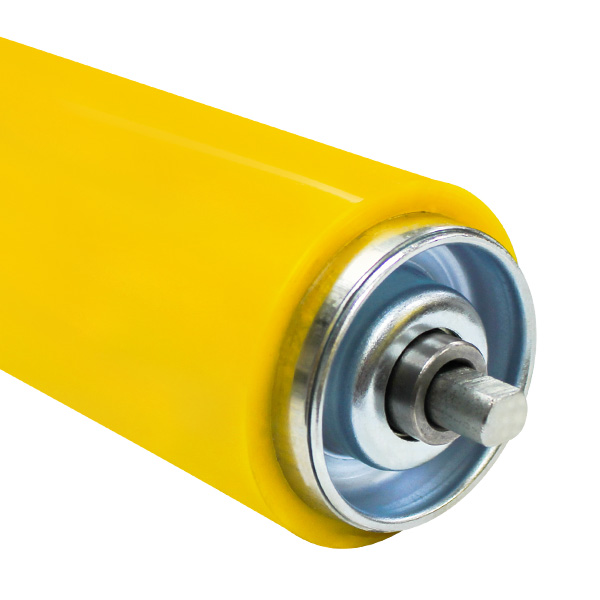

Polyurethane rollers are cylindrical components made from polyurethane material, designed to facilitate movement, transport, and support of various loads in different industrial applications. These rollers can be customized to meet specific needs, making them versatile across multiple industries.

Polyurethane is a synthetic elastomer that combines the elasticity of rubber with the toughness and durability of metal. This unique blend of properties makes polyurethane rollers an excellent choice for applications requiring strength, abrasion resistance, and chemical stability.

Advantages of Polyurethane Rollers

1. Superior Wear Resistance

Polyurethane rollers offer outstanding wear resistance, making them ideal for heavy-duty industrial applications. Unlike rubber, which tends to degrade over time, polyurethane maintains its integrity even under high stress and continuous use.

2. High Load-Bearing Capacity

One of the key advantages of polyurethane rollers is their ability to support heavy loads without deformation. This makes them perfect for conveyor systems, printing machines, and material handling equipment where consistent performance is required.

3. Enhanced Chemical Resistance

Polyurethane rollers exhibit excellent resistance to oils, solvents, and various chemicals. This makes them ideal for use in industries such as food processing, pharmaceuticals, and chemical manufacturing, where exposure to harsh substances is common.

4. Noise Reduction

Unlike metal rollers, polyurethane rollers significantly reduce noise levels in industrial settings. This is especially beneficial in environments where noise control is crucial for workplace safety and comfort.

5. Customization Options

Manufacturers can produce polyurethane rollers in different sizes, hardness levels, and colors to suit specific applications. Custom coatings and surface finishes can also be added to enhance performance in particular environments.

6. Cost-Effectiveness

Due to their long lifespan and low maintenance requirements, polyurethane rollers provide excellent value for money. Their durability helps reduce downtime and replacement costs, making them a cost-effective solution for businesses.

Applications of Polyurethane Rollers

Polyurethane rollers are used across a wide range of industries due to their durability and versatility. Some common applications include:

1. Conveyor Systems

Polyurethane rollers are a key component in conveyor systems, providing smooth and efficient movement of goods in warehouses, distribution centers, and manufacturing plants.

2. Printing Industry

In the printing industry, polyurethane rollers are essential for feeding paper through printing presses and ensuring precise ink application. Their resistance to ink solvents makes them an excellent choice for this application.

3. Textile Industry

Polyurethane rollers are widely used in textile manufacturing for guiding, rolling, and tensioning fabric during production processes.

4. Automotive Industry

The automotive sector relies on polyurethane rollers for assembly line conveyors, paint application systems, and tire manufacturing processes.

5. Food Processing

FDA-approved polyurethane rollers are used in food processing plants to handle and transport food products safely. Their chemical resistance ensures they meet hygiene standards.

6. Medical and Pharmaceutical Industry

Polyurethane rollers are commonly used in medical equipment and pharmaceutical manufacturing due to their precision, reliability, and resistance to contaminants.

Choosing a Trusted Manufacturer for Polyurethane Rollers

When selecting a manufacturer for polyurethane rollers, several factors must be considered to ensure you receive high-quality products that meet your specific needs.

1. Experience and Expertise

A reputable manufacturer should have extensive experience in producing polyurethane rollers. Look for companies with a proven track record and expertise in material selection, engineering, and custom design.

2. Customization Capabilities

Not all applications are the same, so it’s crucial to choose a manufacturer that offers customization options. Whether you need specific dimensions, hardness levels, or coatings, a trusted manufacturer should be able to meet your unique requirements.

3. Quality Control Standards

Ensure the manufacturer follows strict quality control measures. High-quality polyurethane rollers should undergo rigorous testing to guarantee durability, load-bearing capacity, and resistance to wear and tear.

4. Use of Premium Materials

The quality of polyurethane used in roller manufacturing significantly impacts performance. A reliable manufacturer should source premium-grade polyurethane materials to ensure optimal results.

5. Customer Support and Technical Assistance

A trusted manufacturer should provide excellent customer support, offering guidance on selecting the right polyurethane rollers for your application. Technical assistance should also be available for installation and maintenance.

6. Competitive Pricing

While quality is essential, pricing also matters. Look for a manufacturer that offers competitive pricing without compromising on product quality.

Conclusion

High-quality polyurethane rollers are indispensable in various industries, offering superior wear resistance, high load capacity, and excellent chemical resistance. Choosing the right manufacturer is critical to ensuring you receive durable and reliable rollers that enhance productivity and efficiency.

If you are looking for a trusted manufacturer of polyurethane rollers, ensure they offer expertise, customization, premium materials, and excellent customer support. Investing in top-quality polyurethane rollers will not only improve operational efficiency but also save costs in the long run.

For customized polyurethane roller solutions tailored to your industry needs, reach out to a reputable manufacturer today and experience the benefits of high-performance rollers firsthand!

Leave a Reply