Surface Mount Technology (SMT) PCB assembly has revolutionized the electronics industry, enabling the creation of smaller, more complex, and cost-effective devices. By understanding the benefits and capabilities of SMT, you can significantly enhance your product’s performance, reliability, and market appeal.

What is SMT PCB Assembly?

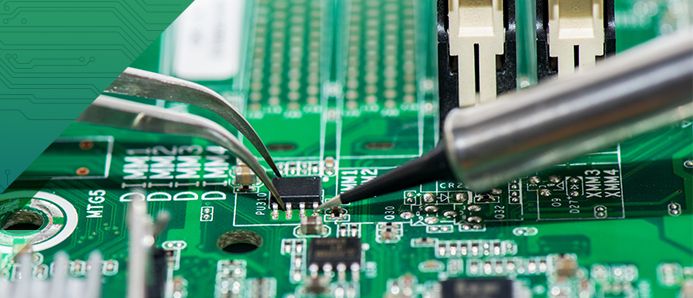

SMT PCB assembly is a process where electronic components are mounted directly onto the surface of a printed circuit board (PCB). This is achieved by using a stencil to apply solder paste to the PCB’s pads, followed by the precise placement of components using automated machines. Finally, the PCB is subjected to a reflow soldering process, where heat melts the solder paste, securing the components to the board.

Key Benefits of SMT PCB Assembly:

- Miniaturization: SMT allows for smaller and more compact designs, reducing the overall size of your product.

- Higher Component Density: More components can be packed onto a smaller PCB, increasing functionality and performance.

- Improved Reliability: SMT joints are more reliable than traditional through-hole soldering, leading to fewer failures and longer product life.

- Faster Assembly: Automated SMT assembly processes are highly efficient, reducing production time and costs.

- Enhanced Performance: SMT enables the use of smaller, high-performance components, leading to improved speed, power efficiency, and signal integrity.

- Cost-Effectiveness: While the initial investment in SMT equipment may be higher, the long-term benefits, including reduced labor costs and improved efficiency, make it a cost-effective solution.

How to Choose the Right SMT PCB Assembly Service Provider:

When selecting an SMT PCB assembly service provider, consider the following factors:

- Experience and Expertise: Look for a provider with a proven track record and experienced engineers.

- State-of-the-Art Equipment: Ensure the provider has modern equipment and technology to deliver high-quality results.

- Quality Control: A robust quality control system is essential to guarantee product reliability.

- Capacity and Turnaround Time: The provider should have the capacity to meet your production needs and deliver on time.

- Cost-Effectiveness: Consider the overall cost, including component sourcing, assembly, and testing.

- Customer Support: Good customer support is crucial for timely communication and issue resolution.

ChinaPCBA: Your Reliable SMT PCB Assembly Partner

ChinaPCBA is a leading provider of SMT PCB assembly services, offering a comprehensive range of solutions to meet your electronic manufacturing needs. With years of experience and a commitment to quality, we deliver high-quality PCBs and assemblies on time and within budget.

By partnering with ChinaPCBA, you can benefit from:

- One-Stop Solution: From design to assembly, we handle the entire process.

- Advanced Technology: Our state-of-the-art equipment ensures precision and efficiency.

- Strict Quality Control: We adhere to rigorous quality standards to deliver reliable products.

- Competitive Pricing: We offer competitive pricing without compromising on quality.

- Excellent Customer Support: Our dedicated team is always ready to assist you.

If you’re looking to enhance your product’s performance, reliability, and market appeal, consider SMT PCB assembly. Partner with ChinaPCBA to bring your electronic product vision to life.

Leave a Reply