In today’s fast-paced manufacturing landscape, precision and efficiency are paramount. When it comes to producing high-volume, consistent plastic parts, few processes rival the versatility and reliability of plastic injection molding. Whether you’re in the automotive, medical, or consumer electronics industry, understanding the nuances of this technology can significantly impact your product’s success.

What is Plastic Injection Molding?

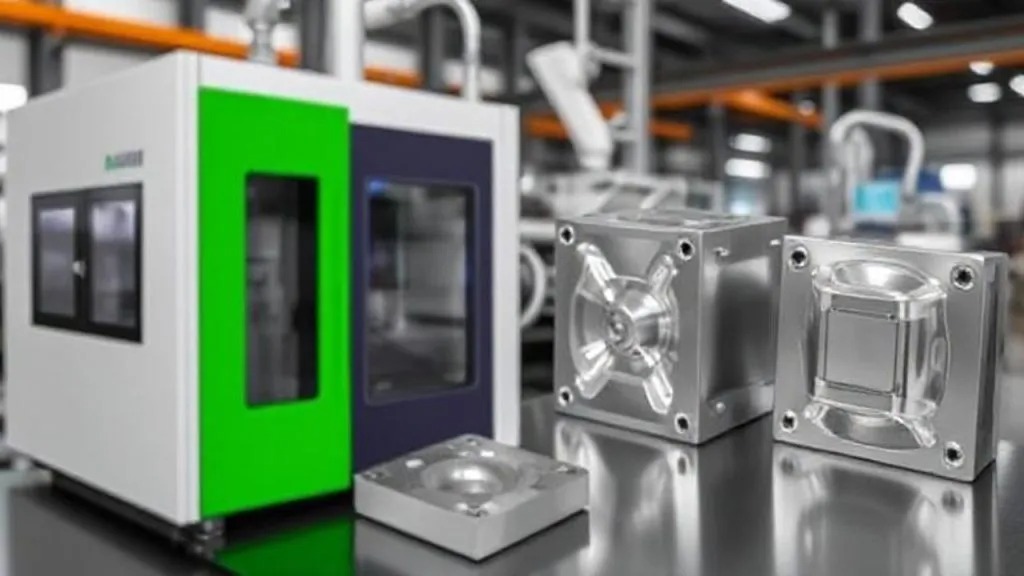

At its core, plastic injection molding is a manufacturing process where molten thermoplastic material is injected under high pressure into a mold cavity. The plastic cools and solidifies, taking the shape of the mold. This process allows for the creation of complex geometries and intricate designs with exceptional accuracy and repeatability.

Why Choose Plastic Injection Molding?

- High Volume Production: Ideal for producing large quantities of identical parts, minimizing per-unit costs.

- Design Flexibility: Enables the creation of complex shapes, intricate details, and varying wall thicknesses.

- Material Versatility: Compatible with a wide range of thermoplastics, each offering unique properties.

- Consistent Quality: Delivers uniform parts with tight tolerances, ensuring consistent performance.

- Cost-Effectiveness: Reduces labor costs and material waste, leading to overall cost savings.

The Importance of Expertise

While the process itself is well-established, achieving optimal results requires expertise in mold design, material selection, and process optimization. This is where partnering with a reputable plastic injection molding service provider becomes crucial.

A skilled provider will offer:

- Advanced Mold Design: Creating molds that ensure efficient production and high-quality parts.

- Material Selection Guidance: Helping you choose the right thermoplastic for your application.

- Process Optimization: Fine-tuning injection parameters to maximize efficiency and minimize defects.

- Quality Control: Implementing rigorous inspection processes to ensure consistent quality.

For businesses seeking reliable and high-quality plastic injection molding solutions, finding a partner with a proven track record is essential. A company like Gree-Ge, which provides comprehensive plastic injection molding services, can be a valuable asset. Their expertise in handling diverse projects and materials makes them a strong choice. You can find more information about their services here: Plastic Injection Molding Services.

Applications Across Industries

The applications of plastic injection molding are vast and diverse. From automotive components and medical devices to consumer electronics and packaging, this technology plays a vital role in numerous industries.

- Automotive: Interior and exterior components, lighting, and electrical connectors.

- Medical: Surgical instruments, medical devices, and diagnostic equipment.

- Consumer Electronics: Housings, buttons, and internal components for electronic devices.

- Packaging: Containers, closures, and packaging components.

Conclusion

In a competitive market, leveraging the advantages of plastic injection molding can provide a significant edge. By partnering with experienced professionals and understanding the process’s capabilities, businesses can achieve high-quality, cost-effective production of plastic parts. If you are looking for more information on the plastic injection molding process, a very helpful resource can be found here: understanding injection molding. Also for a wide variety of plastic materials that can be used in the process, check out this informative page: engineering plastics.

Whether you’re developing a new product or optimizing an existing one, plastic injection molding offers a powerful solution for achieving your manufacturing goals.

Leave a Reply