In today’s fast-paced manufacturing world, precision CNC machining has become an essential technology for producing high-quality, accurate, and efficient parts. From aerospace to medical industries, the demand for precision and consistency is higher than ever. In this blog, we’ll explore the benefits, applications, and advancements in precision CNC machining.

What is Precision CNC Machining?

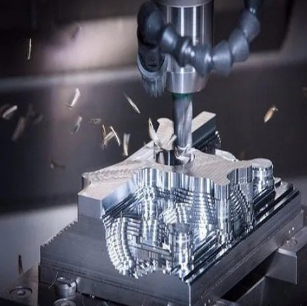

Precision CNC machining is a process that utilizes computer-controlled machine tools to create components with extremely tight tolerances and superior accuracy. This advanced technology eliminates human error and ensures that every part meets exact specifications.

Benefits of Precision CNC Machining

-

Unmatched Accuracy – CNC machines can produce components with micron-level precision, making them ideal for industries that require extreme accuracy.

-

Consistency and Repeatability – Once a program is set, CNC machines can create identical parts with no deviation, ensuring quality across large production runs.

-

Enhanced Efficiency – CNC machining reduces material waste and speeds up production time, leading to cost-effective manufacturing.

-

Versatile Material Compatibility – From metals like aluminum and titanium to plastics and composites, CNC machines can handle a wide variety of materials.

-

Improved Safety – Automation reduces the need for manual labor, minimizing workplace injuries and errors.

Applications of Precision CNC Machining

Due to its accuracy and efficiency, precision CNC machining is widely used in various industries, including:

-

Aerospace – Manufacturing of aircraft components that must adhere to strict safety and performance standards.

-

Medical – Production of surgical tools, implants, and medical device components.

-

Automotive – Creating complex engine parts, transmissions, and chassis components.

-

Electronics – Fabrication of enclosures, connectors, and circuit board components.

-

Defense – Production of firearms, military-grade equipment, and specialized tools.

Advancements in Precision CNC Machining

Modern advancements in precision CNC machining have further enhanced its capabilities. Technologies such as 5-axis machining, AI-driven automation, and real-time monitoring allow manufacturers to achieve even higher precision and efficiency. These improvements enable the creation of complex geometries and reduce production lead times.

Why Choose Precision CNC Machining?

For businesses that require superior accuracy, repeatability, and efficiency, precision CNC machining is the ideal solution. Whether you need a single prototype or a high-volume production run, this technology ensures the highest quality standards are met.

If you’re looking for expert precision CNC machining services, check out MXYMachining. Our state-of-the-art CNC machines and experienced team are ready to bring your projects to life with unmatched precision and reliability.

Leave a Reply