PCB assembly is the backbone of modern technology. From the smartphones in our hands to the laptops powering our work, PCBs are the unsung heroes that keep our gadgets – and our lives -running smoothly. But for businesses and innovators, navigating the complexities of PCB assembly can be downright intimidating. This is where outsourcing to a professional PCB assembly manufacturer enters the scene, offering a sustainable and efficient path forward.

What Is PCB Assembly?

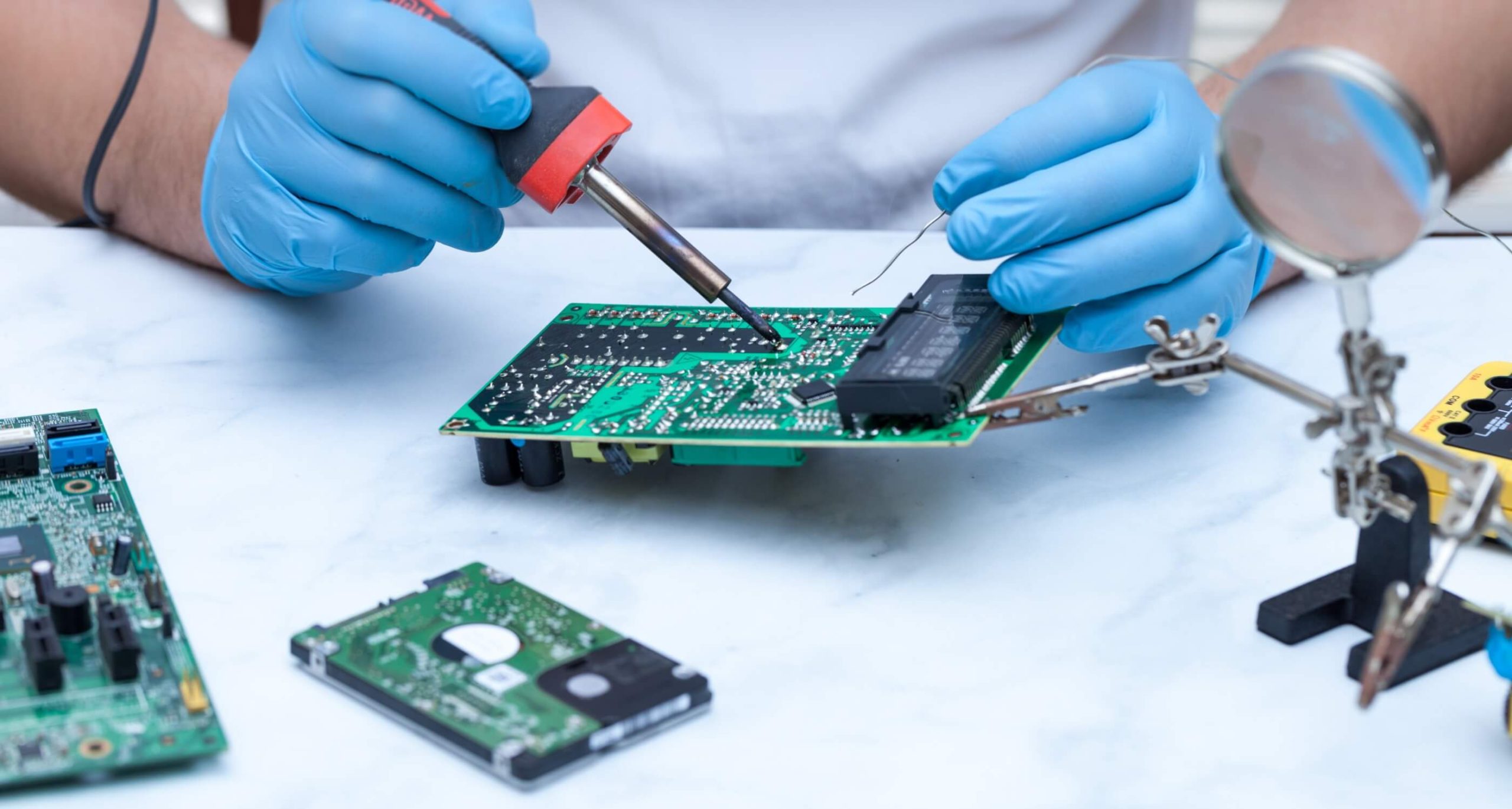

PCB assembly is the process of mounting and soldering electronic components on a printed circuit board to create a fully functional circuit. It’s far from just sticking components together; it’s an intricate process that requires precision, expertise, and advanced equipment.

The major steps in PCB assembly include:

- Solder Paste Application: A stencil applies the solder paste to the areas of the board where components are going to be mounted.

- Component Placement: Automated machines mount resistors, capacitors, and microprocessors on the board.

- Soldering: Reflow ovens or wave soldering techniques effect soldering.

- Inspection and Testing: Quality check that includes visual inspections, X-rays scans, and functional tests ensure that the board works properly.

One thing is true: PCB assembly is a science and an art. And so, for many startups, the engineering firms or companies without proper in-house capacity, this depth of complexity tends to be overwhelmingly challenging. But that’s why this is such an important game changer: outsourcing.

What are some of the key benefits of subcontracting your project to a professional PCB assembly manufacturer?

Having talked about the foundation, it’s now time to find out why the outsourcing of your PCB assembly process to a professional manufacturer should top your list of priorities. This is how it can revolutionize your process – and how it positively affects sustainability and the bottom line.

- Expertise and Advanced Technology

Industry experts, professional PCB assembly manufacturers employ specialized, high-tech equipment and processes developed to be accurate, reliable, and scalable. By outsourcing to the pros, you’re tapping into years of knowledge built up by them through experience and innovation-all without the hassle of setting it up or training. Bonus: advanced manufacturing processes tend to be waste-friendly and highly efficient, so you’ll feel good about the environment with a professional manufacturer.

- Cost efficiency

Establishing an in-house PCB assembly plant is very expensive. Imagine, expensive machinery and the cost to train the workers and run an assembly line. Outsourcing does all that for you, saving money and letting you stick to what matters: designing and growing your business.

Professional manufacturers also obtain materials in volume which reduces the expense of the parts and then transfer the savings to you. Efficient manufacturing processes also reduce the possibility of mistakes, saving you money on rework and wasted materials.

- Better Quality and Reliability

Professional PCB assembly manufacturers use stringent quality control measures to produce highly reliable results. Industry standards such as ISO 9001 certification or RoHS compliance ensure that the end product not only meets but exceeds expectations.

With advanced testing capabilities – such as in-circuit testing, automated optical inspection, and functional testing – you will know your PCBs are free of defects and ready for scale.

- Scalability and Flexibility

Professional manufacturers can handle the needs of small startups and growing businesses. Whether you need a few prototypes or a full production run, they can accommodate your needs seamlessly.

By outsourcing, you retain the flexibility to scale production up or down based on demand, without being tied to the fixed costs of an in-house operation.

- Commitment to Sustainability

Today’s businesses must prioritize eco-conscious practices – and professional PCB assembly manufacturers help make this possible. Many have adopted green initiatives like energy-efficient machinery, minimal waste production, and recyclable materials.

Outsourcing your PCB assembly to an eco-friendly manufacturer means you’re reducing your environmental impact while still achieving exceptional results. And in a world that values sustainability, that’s a win-win situation.

- Global Insights, Local Support

Outsourcing to a well-established PCB assembly manufacturer often connects you with global expertise. However, many top-tier manufacturers maintain localized support to provide personalized service. This ensures clear communication, timely delivery, and strong collaboration while leveraging a global supply chain.

Conclusion

When you work with a professional PCB assembly manufacturer, you are not just delegating a job-you are investing in a strategic partner who helps bring bold, innovative ideas to market. Are you ready to discover sustainable, innovative solutions for your next PCB project? Get in touch with a professional today to see how they can take it to the next level. The possibilities are endless with the right partner.

Leave a Reply